DIGITAL SUPPLY CHAIN

Driving the transformation from cost center to profit center

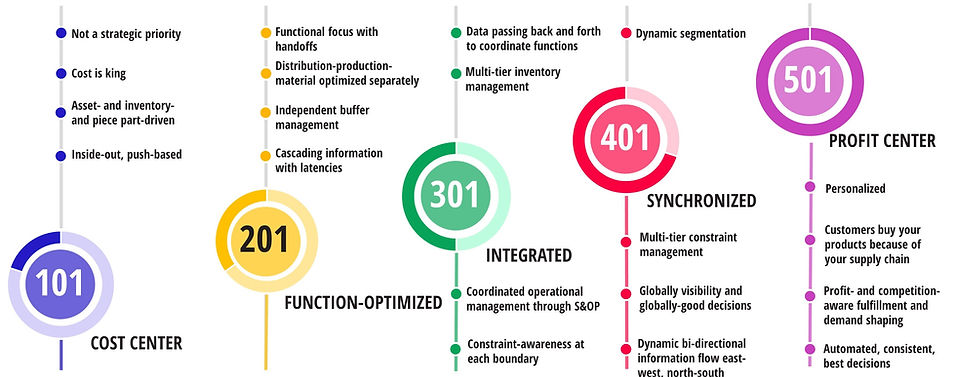

Stages of Digital Transformation

Worldlocity Supply Chain Profit Center Maturity Model

101 - Cost Center

The era of the push-based supply chain was over a long time ago. However, elements of this thinking still exist in many supply chains today. The primary driver in these supply chains is to achieve the highest possible volume at the lowest possible cost, irrespective of real demand. This was successful when there was strong control over sales channels and customers.

For some historical perspective, see "The Economy's Dark Continent."

201 - Function-Optimized

Functional optimization is the process of optimizing individual functions, without consideration of the overall goals of the system. Each department, or function may achieve its goals, but the overall goal of the system may not be achieved. Elements of functional optimization are important building blocks, but must be put into the context of overall system thinking in order to move up the maturity curve. Much of the early work in operations research and associated optimization software was focused on functional optimization because of limited computer resources.

301 - Integrated

The early 2000s saw the beginnings of a focus on integration and integrated supply chain management. This is the stage where many companies find themselves today. Individual functions are upstream and downstream integrated, with data passing back and forth, and constraint sharing at the boundaries of each function. Monumental IT efforts have been undertaken in order to integrate different different data models and architectures so that functions can talk back and forth and share goals. This is also a stage when multi-tier inventory management and operational S&OP take hold, along with the beginnings of segmentation strategies.

401 - Synchronized

Synchronized means that functions are time- and function-linked to demand and with each other, and are furthermore linked back to the business objectives of the enterprise. In the synchronized stage, there is a continuous pulse coming back from the supply chain. This pulse signal is compared to the objective function for the enterprise and corrective action is taken. Synchronization is fundamentally different from integration; integration allows for better localized decisions. But these decisions may not be synchronized back to business goals and real demand and data in different functions may not be time-synchronized.

501 - Profit Center

Once a supply chain is synchronized, there is an opportunity to evolve into a differentiated service that is viewed as part and parcel to products. In some cases, the supply chain may become the product; in other words, it is the reason that customers choose your products over those of your competitors. This level of capability requires detailed knowledge of customer preferences and cost-to-serve, along with synchronization to business goals at the intersection of geography, product, channel, and customer. This requires a control loop with the ability to process data in real-time and apply algorithms; this needs to be augmented with a learning loop which captures data from the control loop and periodically modifies decision algorithms.

Core Principles for SCM Software

Below are links to papers that offer core concepts at the intersection of software and supply chain management

Supply chain management software is in need of an overhaul. The architectural paradigm that has been in place for the past twenty years is limited in its ability to rapidly address the significant and continuous change brought on by increasing customer expectations and new competition. This paper examines the problem and describes ten key elements important for future solutions.

Setting up an omnichannel supply chain requires end-to-end system thinking and leveraging technologies to create multiple virtual supply chains across the physical asset and labor base. This paper defines the omnichannel challenge, discusses the economics behind it and offers ten key steps to consider in setting up an omnichannel strategy that is synchronized to your business goals.

Supply chain segmentation is the process by which companies can create profitable one-to-one relationships between their customers and their supply chain. The goal is to find the best supply chain processes and policies to serve each customer and each product at a given point in time to maximize customer service and company profitability. This paper explains the concepts and reasons for segmentation and discusses tend key areas where policies and technology are important to achieving its goals.

S&OP has evolved from a long-range planning process to a planning process coupled with a sense-and-respond capability designed to steer operations to plan achievement. This paper examines how control engineering concepts can be applied to the traditional S&OP process, turning it into a close loop management process, instead of a traditional open-loop planning process. S&OP has evolved

Microservices are today's flavor of web services. Microservices are self-contained units of software code that have no outside dependencies, except APIs. But the concept of services and APIs have been around a couple of decades now. This paper examines how services can be used to solve supply chain management problems. This approach is important for both legacy and new systems. This is part of a long trend towards unbundling software capabilities into capabilities that can be accessed synchronously and asynchronously through APIs. This unbundling provides much more flexibility in plugging in and out software capabilities.